"Along the poetic banks of the Co Chien River, the brick kilns of Mang Thit stand tall, glowing red like a miniature crimson kingdom by the river."

An Phuoc, Minh Chau, Tan Sung, Tay Son… each kiln has its own name, but people still refer to them by the familiar name "Mang Thit" - the district that cradles these brick kilns, still ablaze day and night.

Journey back to Mang Thit

From Tra Vinh, we traveled along National Highway 53 to reach the Mang Thit area in Vinh Long, renowned for its brick kilns, some over 100 years old. Stretching more than 30 kilometers, these kilns line up along the banks, forming a small kingdom by the Co Chien River.

It's no coincidence that Mang Thit, Vinh Long became fertile ground for the establishment of these brick kilns. Blessed by nature, Vinh Long's soil is rich in valuable clay. Recognizing the value of this resource early on, the Chinese residents in this southern province began building the first brick kilns. For convenience in production and trade, the Co Chien riverside became the ideal location for constructing the kilns. When transportation was less developed than it is now, waterways were the primary route for moving goods in this river-laden region of the Mekong Delta.

At first, the brick kilns appeared sporadically along the Co Chien River. Later, as the demand for Mang Thit bricks grew, more kilns were built. Over time, the riverbank transformed into a dense network of brick and ceramic production facilities, with each kiln typically operated by a family, passed down through generations.

"Along the Co Chien River, the brick kilns continue to glow day and night, as steadfast and enduring as the love the kiln owners have for this century-old traditional craft."

At its peak, the kiln system along the Co Chien River numbered in the thousands, with more than 3,000 kilns producing bricks and tiles. Although the number of kilns has decreased, the quality of the bricks has improved significantly. Initially, the kilns only produced traditional bricks and yin-yang tiles using manual methods. By 1960, with the mechanization of the kilns, they began producing additional types of bricks, such as hollow bricks and terracotta tiles, known for their sharpness and uniformity, which are now exported abroad.

"The presence of the brick kilns marks a transformation in cultural and natural flows. The mechanization of the kilns represents a shift in production and the times."

Exploring the brick kilns

It was a rainy morning in Vinh Long, but the cooler, more pleasant atmosphere made up for it. After some inquiries, we found the road leading to the Mang Thit kilns. Traveling along this road, we were awestruck by the sight before us.

Tall, imposing, somewhat ancient and silent, the brick kilns, standing between 7 to 15 meters high, emerged one after another. These round tower-shaped kilns, narrowing towards the top, are built from the very bricks they produce. It's unclear how many bricks were needed to construct these massive kilns, but it must have been hundreds of thousands, stacked, interlocked, and supporting one another.

"In the dampness of the morning rain, we could distinctly sense the characteristic scent of clay, of wet baked earth absorbing rain after scorching hot days - a unique, indescribable aroma."

Stopping by a production facility along the way, we had the chance to explore the inside of a brick kiln. A middle-aged woman warmly welcomed and guided us. After chatting with her, we learned that the facility originally had two smaller kilns. However, a few years ago, they were combined into a larger kiln to save on labor costs and increase efficiency.

The current kiln stands 15 meters tall and can hold up to 430,000 bricks. Each batch takes 5-7 days to load and arrange inside the kiln, and another 30 days to fire, resulting in high-quality bricks. The bricks produced here are durable, high-load-bearing two-hole bricks, popular in construction—these are the same types of bricks that have been produced in Mang Thit for centuries.

We arrived just as the workers were loading bricks into the kiln. At first glance, the task seemed easy, thanks to the machinery that lifts the bricks from the ground to the kiln entrance. However, that was just our initial impression from watching. Once we had the opportunity to climb the ladder to the kiln entrance, step inside, and experience it ourselves, it was a completely different story.

Even just climbing the ladder to the kiln entrance, as well as moving inside, was a significant challenge in terms of height and dexterity. The ladder was steep, and inside the kiln, bricks were stacked densely. If we weren’t careful, we could easily topple the carefully arranged stacks - the fruit of the workers’ meticulous efforts over the past few days.

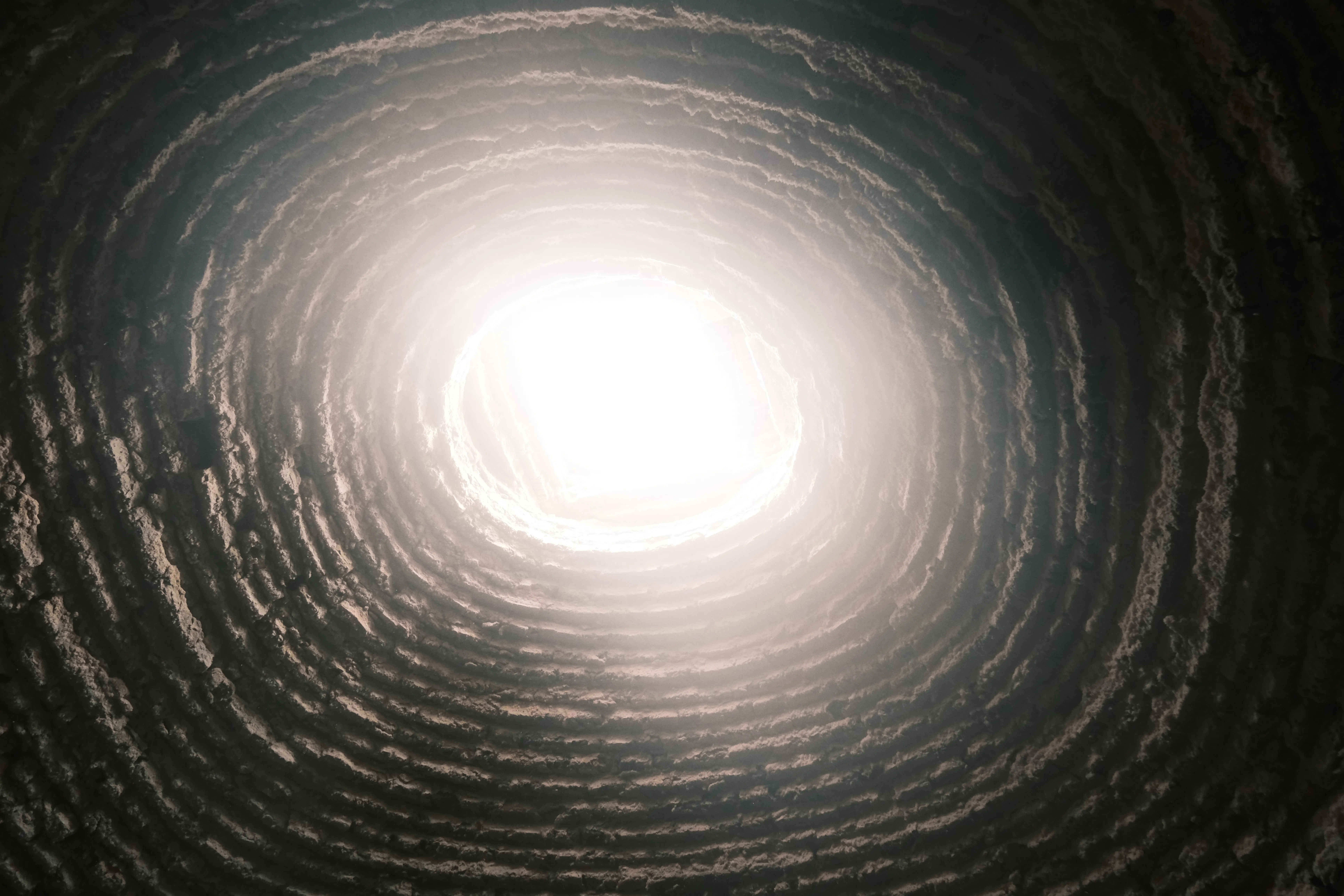

"Once inside the kiln, the mesmerizing scene made us momentarily dazed, feeling that all the effort of climbing was entirely worthwhile."

Inside the kiln, there were no windows or gaps around, only a small skylight overhead, yet it provided just enough light for the space below. There were nine of us, including the workers stacking bricks, all sharing that small patch of light, yet it felt just right and comfortable.

Inside the kiln was cool, with walls coated in thick, white ash. If someone accidentally brushed against the walls, they’d be covered in ash from head to toe, needing a good while to clean off.

We observed the workers, their hands moving swiftly between the brick conveyor and the stacking area. Each time, four bricks were transported and neatly stacked in place. It must have taken years of dedication to the kiln, the ladders, and the job to reach such a level of proficiency and precision.

As we watched, chatted, and documented the labor of these workers, we were occasionally startled when we accidentally looked down through the gaps between the brick stacks. The spaces were pitch-black, seemingly bottomless, giving the impression that if we dropped our phones or anything else down there, there would be no way to retrieve it.

Bidding farewell to the workers and the kilns along the Co Chien River, we left Mang Thit as the rain stopped, the sky cleared, and the sun began to rise over the red kilns. As we moved further away, we hoped that we would soon have the chance to return to Mang Thit, to the Co Chien. And when we do, may the kilns here still be bustling and glowing with flames day and night, as they always have been…

—------

CREDIT:

- Photography: Luan Nguyen

- Content: Giang Huynh

- Design: Luan Nguyen